Weld Settings

Weld Settings

Table of contents

About

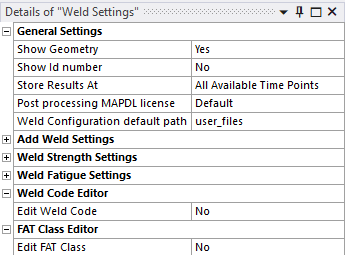

General preference for welds are managed by the “Weld Settings” object. This is useful for turning the plotting of “Weld Id number” on/off or to edit the default values. The object is also used for editing or adding weld codes. The object is optional and can be deleted from the model.

Usage

Click “Weld Settings” to add the Weld Settings object to the model tree.

Existing data in the preference file “weldStrengthPref.py” and “weldFatiguePref.py” is used when the settings is added.

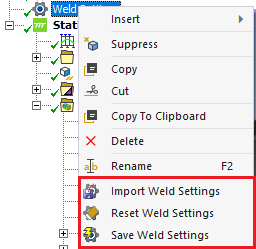

Right-click on Weld Settings to access the context actions:

- Import Weld Settings from a selected previous version.

- “Reset Weld Settings” to revert the Weld Settings.

- “Save Weld Settings” to update (and overwrite) the global preference files “weldStrengthPref.py” and “weldFatiguePref.py” right-click and select .

A pop-up question “Overwrite existing Weld Setting defaults?” prompts the user to confirm or cancel the save.

(A backup copy of the app default values are saved in the files “weldStrengthPrefDefault.py” and “weldFatiguePrefDefault.py”.) - “Apply Settings on results” to apply the “Result Item Default”, “Calculate Time History”, “Default Code” and “Material Default” to all results.

- “Install License File” to fill in the license credentials from a license file.

- “Check Out License” to activate and check out the license.

- “Check License Status” to display current license information.

The Weld Codes and FAT Class are not modified by the “Save Weld Settings”.

They have separate save buttons, see the sections below.

Import Weld Settings

When updating/migrating from a previous version of Weld Toolkit use the context action “Import Weld Settings” to browse for the folder with the preference files.

The General Settings from the source folder (weldStrengthPref.py, weldFatiguePref.py) are loaded to the current Weld Settings object so the changes can be inspected before using the “Save Weld Settings”.

The import of Materials, Weld Code and FAT Class will import the data from corresponding files (Materials.json, weldCodes.json, fatClassDict.json) and add only if a name is missing, i.e. not over-writing existing names.

A pop-up window will display all the identified imports with the option to confirm (OK) or abort (Cancel) the import.

The ACT Log File will list the name of all imported items.

If you have made edits of the existing codes, e.g. “Eurocode 3”, in previous version you have to apply the changes using the Weld Code Editor or in a text editor on the corresponding files.

General Settings

The General Settings defines the default values for the different features. You may always edit the properties on the individual load/result object when using them.

| General Settings | |

|---|---|

| Show Geometry | Yes (Default)/No. Default value for Weld Group property “Show geometry”. |

| Show Geometry on Results | Yes (Default)/No. Default value for Weld Group property “Show Geometry on Results”. |

| Show Id number | Yes (Default)/No. Default value for Weld Group property “Show Id number” and to plot section Id number on weld results. |

| Store Results At | All Available Time Points (Default)/Last Time Point (i) |

| Post processing MAPDL license | (Default) Specify custom license increment to use in post processing (ii). |

| Weld Configuration default path | user_files (Default)/workingdir. Specify Save/Import default location. |

| Check for new version at start | Yes (Default)/No. Enable/Disable app version check at start. |

| Add Weld Settings | |

| Nonlinear effects | Yes/No (Default). Use plasticity models defined in the selected material. |

| Weld Element Order | Linear/Quadratic (Default). Weld element order. |

| Weld Throat elements | 1/2 (Default)/3/4. Number of throat elements. |

| Weld Element aspect ratio | 2 (Default). Weld element length vs. throat size ratio. |

| Weld minimum angle [deg] | 0 < angle < 90. Fillet Weld minimum angle. |

| Weld maximum angle [deg] | 90 < angle < 180. Fillet Weld maximum angle. |

| Weld Gap ratio | 0.5 (Default). Maximum Gap size vs. Throat size. |

| Intermittent Weld minimum length | 30 mm (Default). Minimum weld seam length. |

| Intermittent Weld min length factor | 6 (Default). Minimum weld seam length factor of throat size. |

| Intermittent Weld max spacing | 200 mm (Default). Maximum spacing between weld seams. |

| Contact adjustment | Yes (Default)/No. Contact adjustment to morph weld leg contacts to target faces. |

| Export Weld Group Cdb | Yes/No (Default). Export a MAPDL archive file (cdb) of the “Add Welds” during solve. |

| Weld Strength Settings | |

| Default weld size | 3 mm (Default). Minimum (starting) value when calculating the weld throat size. |

| Weld size increment | 1 mm (Default). Increment value when calculating the weld throat size. |

| Maximum Weld size | 99 mm (Default). Maximum value when calculating the weld throat size. |

| Result Item Default | Wuf (Default). Weld Strength result item. |

| Calculate Time History | Yes/No (Default). Sets “Calculate Time History” on new results. |

| Plot Weld Node CSYS | Yes/No (Default). Plot weld node coordinate system on evaluation. (Debug feature) |

| Condensed Segment CSV | Yes/No (Default). Write only one node per segment in the result csv file. |

| Print Group average in Weld Report | Yes/No (Default). Write group average as section Id = 0 in the weld report. |

| Weld Force Extraction | Contact Element (Default)/Underlying Element (iii) |

| Weld Fatigue Settings | |

| Default Load Type | Zero Based/Fully Reversed (Default)/Ratio/Load Combination/Load Scanning/Solution Combination/Solution Scanning |

| Default Cycles per block | 1 (Default). Cycles per block for new results. |

| Automatic Weld Fatigue Legend | Yes (Default)/No |

| Signed stress range | Yes/No (Default). If “Yes” the sign of the stress is kept for “Zero based”, “Fully Reversed” and “Ratio” load cases. |

| CSV - FAT Class | IIW FAT160 steel (Default). FAT Class name for new results. |

| Linearized - FAT Class | IIW FAT160 steel (Default). FAT Class name for new results. |

| Linearized - Stress Type | Linearized Absolute Principal Stress (Default). Stress Type for new results. |

| Linearized - Stress Item | Membrane+Bending (Default). Stress Item for new results. |

| Linearized - Always plot path | Yes (Default)/No. Display path vectors on solved results. |

| Structural - FAT Class | User defined (Default). FAT Class name for new results. |

| Structural - Stress Type | Seqv/Snormal/Sbending/Sstruct (Default)/Sparallel/Stotal/Tparallel/Tnormal/Ttotal. Stress Type for new results. |

| Structural - Result averaging | Local (Default)/Section. Average stress. |

| Nominal - FAT Class | IIW FAT160 steel (Default). FAT Class name for new results. |

| Nominal - Stress Type | Principal (Default)/Sum of Principal/Stress Intensity/Equivalent/Normal X/Normal Y/Normal Z/Shear XY/Shear YZ/Shear XZNormal. Stress Type for new results. |

| Nominal - Always plot stress axis | Yes (Default)/No. Display stress axis on solved results. |

| Hot-Spot - FAT Class | IIW FAT90 steel (Default). FAT Class name for new results. |

| Hot-Spot - Stress Type | Normal (Default)/Parallel/Shear/Shear (Max)/Principal (no limit)/Principal (IIW limit)/Principal (Normal)/Principal (Parallel)/Equivalent/Equivalent (DNV)/Principal (Parallel)/Equivalent/Equivalent (DNV) |

| Hot-Spot - Extrapolation Type | Constant/Linear (Default)/Quadratic. Extrapolation Type for new results. |

| Hot-Spot - Default thickness | 0 mm (Default). Material thickness for new results. |

| Hot-Spot - Extrapolation Constant | [1.0] (Default). List of extrapolation factor, a, for Constant. |

| Hot-Spot - Extrapolation Linear | [0.4,1.0] (Default). List of extrapolation factors, a & b, for Linear. |

| Hot-Spot - Extrapolation Quadratic | [0.4,0.9,1.4] (Default). List of extrapolation factors, a & b & c, for Quadratic. |

| Hot-Spot - Project lines on geometry | Yes (Default)/No. Project Hot-Spot lines on geometry. Graphics feature, does not influence results. |

| Hot-Spot - Always plot lines | Yes (Default)/No. Plot Hot-Spot extrapolation lines on solved results. |

| Hot-Spot - Plot nodes (Debug) | Yes/No (Default). Plot Hot-Spot nodes and extrapolation lines on evaluation (Debug feature). |

| Effective Notch - FAT Class | IIW FAT225 R1 steel (Default). FAT Class name for new results. |

| Effective Notch - Stress Type | Tangential (IIW default)/Parallel/Principal/Sum of Principal/Stress Intensity/Equivalent/Shear (Max). Stress Type for new results. |

| Effective Notch - Plot Notch Vectors | Yes/No (Default). Plot Notch stress vectors on evaluation (Debug feature). |

| Weld Code Editor | |

| Edit Weld Code | No (Default)/New/Eurocode 3/AISC 360-16 (iv) |

| FAT Class Editor | |

| Edit FAT Class | No (Default)/Yes/New S-N Table/”S-N Table name” |

| License Settings | |

| Edit License Settings | Yes/No (Default) If “Yes” displays the following properties. |

| Customer ID | Used to update and save the Customer ID provided by EDRMedeso. |

| License Key | Used to update and save the License Key provided by EDRMedeso. |

| License borrowing time (days) | 0 <= time <= 31 days (Default 1). |

(i) Store Results At

If the Analysis Setting/Output Controls is “Store Results At = All Time Points” and the result file contains many sub steps this setting can limit post processing to “Last Time Point” for each load step to speed up post processing time in the following cases:

- Weld Strength results when using “By = Maximum Over Time” or if “Calculate Time History = Yes”.

- Weld Fatigue results when using “Load Type = Load Scanning”.

If the Analysis Setting/Output Controls is “Store Results At = Last Time Point” then this setting does not influence the post processing time.

It is possible to change the property back to “All Available Time Points” to post process at a specific sub step or time point within a load step without clearing the solution given that the solution was solved with “All Time Points”.

(ii) Post processing MAPDL license

Default,Mechanical Pro,Mechanical Premium,Mechanical Enterprise,Mechanical Enterprise PrepPost,Mechanical Enterprise Solver

(iii) Weld Force Extraction

Weld Strength force extraction can now use Formulation = “MPC” for bonded contacts if Weld Force Extraction = “Underlying Element”. See Bonded contact vs. multi-body for more information.

(iv) Edit Weld Code

When selecting “New” an empty set of properties are displayed.

When selecting an existing code the corresponding properties are loaded.

Weld Code Editor

The Weld Code Editor is used to modify an existing code or to create a new.

The interface loads data from the file “weldStrengthPref.py”. New and modified codes are saved in a separate file, “WeldStrength.json” in the app installation folder. This file (if it exists) is used and replaces the app original data when post processing.

To revert to the app original data delete (or rename) the file “WeldStrength.json”.

When migrating to a new version of Weld Toolkit use the context action Import Weld Settings.

The principle for creating a weld code is to define:

- One or more Material grades that defines the nominal design strength.

- An expression for the equivalent stress; “Seqv = weldSeqv(Weld Section Parameters)”.

- One or more expressions for Design Resistance Parameters.

The Weld Utilization Factor is defined as the maximum from all defined design stress and design resistance: Wuf = max(Seqv/FuSeqv, Sn/FuSn, …).

| Weld Code Editor | Description |

|---|---|

| Edit Weld Code | “Selected code” |

| New Weld Code Name | Rename or delete the selected code (i) |

| Default Weld Code | Yes/No Assign current code as the new default code. |

| Save Weld Code | Apply/Cancel Click to save/update (or cancel) |

| Material Default | Default material grade for design code. |

| Material grade | Tabular Data editor for Fy, Fu, alfaw, betaw, gammaM2 and gammaL. |

| Design stress | |

| Equivalent Stress, weldSeqv | Expression weldSeqv. Function of any Weld Section Parameter. |

| Stress Type | Absolute Stress (Default)/Positive Stress Set if evaluation should use “Absolute” or “Positive” stress. |

| Stress Type, Read Only | Yes (Default)/No Set if Stress Type should be marked as “Read Only” |

| Floating Factor | Floating average length factor. |

| Design Resistance | |

| Equivalent Stress, FuSeqv | Expression FuSeqv. Function of any design resistance parameter. |

| Normal Stress, FuSn | Expression FuSn. Function of any design resistance parameter. |

| Parallel Stress, FuSp | Expression FuSp. Function of any design resistance parameter. |

| Normal Shear Stress, FuTn | Expression FuTn. Function of any design resistance parameter. |

| Parallel Shear Stress, FuTp | Expression FuTp. Function of any design resistance parameter. |

| Total Shear Stress, FuTt | Expression FuTt. Function of any design resistance parameter. |

| Bending Stress, FuSb | Expression FuSb. Function of any design resistance parameter. |

| Structural Stress, FuSs | Expression FuSs. Function of any design resistance parameter. |

| Total Normal Stress, FuSt | Expression FuSt. Function of any design resistance parameter. |

(i) New Code Name

If using the same name the code is updated.

If naming “delete”, “del”, “clear” or “remove” the selected code is deleted.

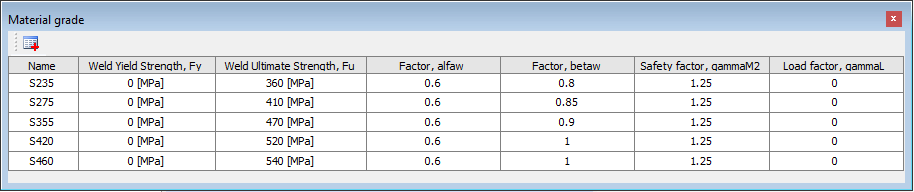

Material grade

The material tabular editor loads the available Material Grades from the selected code.

The following restrictions apply:

- Fy >= 0, Default Fy = 0.0 (Optional)

- Fu > 0

- alfaw > 0, Default αw = 0.6

- betaw > 0, Default βw = 1.0

- gammaM2 > 0, Default γM2 = 1.0

- gammaL >= 0, Default γL = 0.0 (Optional)

If gammaL > 0 it sets the result Scale Factor Value.

Weld Section parameters

The weld section parameters are used to define the Equivalent Stress, weldSeqv and to be used to evaluate the weld utilization.

| Parameter | Description |

|---|---|

| Sn (i) | Normal stress perpendicular (normal) to weld section. |

| Tn (i) | Shear stress (in plane to weld section) perpendicular (normal) to weld axis. |

| Tp | Shear stress (in plane to weld section) parallel to weld axis. |

| Tt (i) | Total shear stress, Tt = sqrt(Tn^2+Tp^2). |

| Sp | Normal stress parallel to weld section (“stretching” the weld). |

| Sb | Bending stress, Sb = MY/W, MY: Local weld bending moment, W = L*a^2/6 (L: local weld length, a: throat thickness in weld section). |

| Ss | Maximum Structural stress Ss = abs(Sn) + abs(Sb) (If stressType = ‘Positive Stress’; Ss = Sn + abs(Sb)). |

| St (i) | Total normal stress, St = sqrt(Sn^2+Tn^2). |

| phi | Angle between weld reaction force and weld axis in radians. |

(i) Stress item

The stress items (and Seqv) are evaluated at the selected Result Location.

Design Resistance parameters

The design resistance parameters are used to define the individual Design Resistance values.

| Parameter | Description |

|---|---|

| Fy | Weld yield strength |

| Fu | Weld ultimate strength |

| alfaw | Shear strength factor, αw |

| betaw | Correlation factor, βw |

| gammaM2 | Safety factor (strength), γM2 |

| phi | Load angle relative to weld axis |

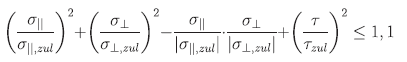

Dimensionless Design stress/resistance

The Equivalent Stress, weldSeqv parameter can be used to define a dimensionless expression that combines weld section stress parameters and design resistance parameters, e.g.

This equation can be implemented by defining the following expressions for “weldSeqv” and “FuSeqv;

weldSeqv:

convFu*((Sp/FuSp)**2 + (Sn/FuSn)**2 - abs(Sp/FuSp)*abs(Sn/FuSn) + (Tt/FuTt)**2)

FuSeqv:

convFu*1.1

To manage different display units the unit conversion parameter “convFu” must be included in the “weldSeqv” and “FuSeqv” expression, otherwise the result item “Seqv” (utilization) will only be displayed correct if using SI (m, kg) as display unit.

FAT Class Editor

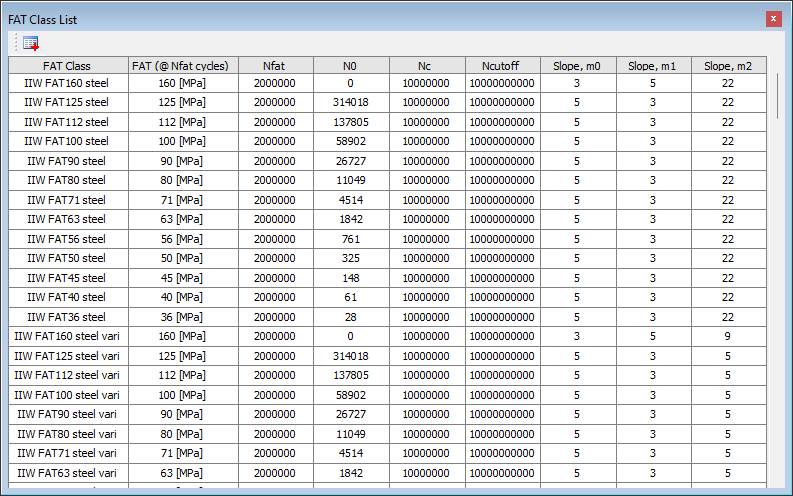

The FAT Class Editor is used to modify or add new FAT class S-N data.

The interface loads data from the file “weldFatiguePref.py”. The modified data is saved in a separate file, “fatClassDict.json”, in the app installation folder. This file is loaded and replaces the app original data when postprocessing.

To revert to the app original data the file “fatClassDict.json” can be deleted. When migrating to a new version of Weld Toolkit use the Import Weld Settings to keep your custom FAT data.

| FAT Class Editor | Description |

|---|---|

| Edit FAT Class | No (Default)/Yes/New S-N Table/”S-N Table name” |

| New FAT Class Name | Rename or delete the selected S-N Table (i) |

| Save FAT Class | Apply/Cancel Click to save (or cancel) |

| FAT Class Table | Tabular Editor for bi (or tri)-linear FAT data. Visible if “Yes” |

| S-N Table | Tabular Editor for S-N data. Visible if “S-N Table” |

(i) New FAT Class Name

If using the same name the selected S-N Table is updated when clicking “Save FAT Class”.

If naming “delete”, “del”, “clear” or “remove” the selected “S-N Table” is deleted.

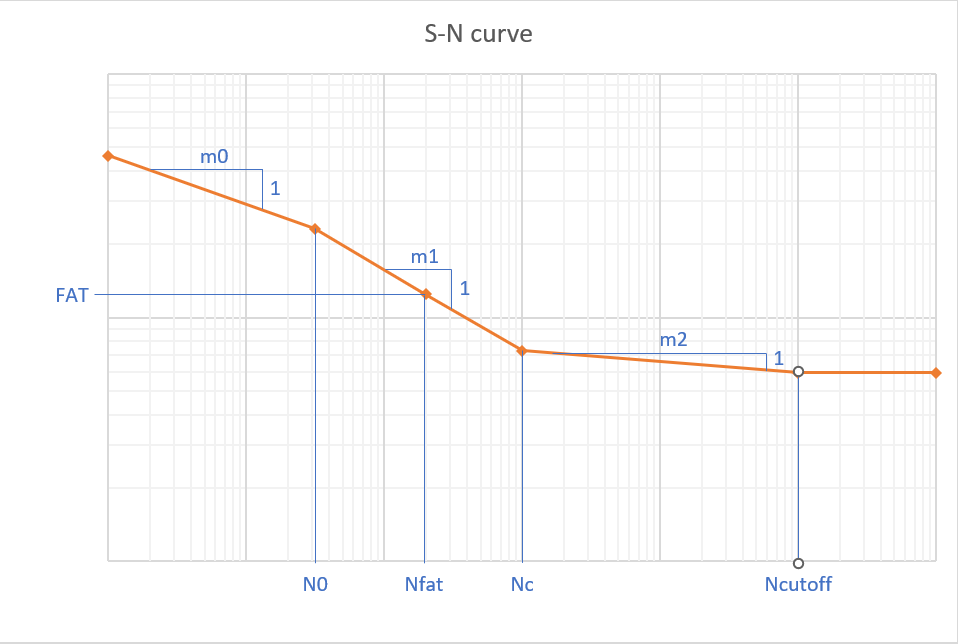

The FAT Class Table is used to edit (or add) bi (or tri)-linear FAT data.

The following restrictions apply to FAT Class Table:

- FAT > 0

- 0 <= N0 < Nfat < Nc < Ncutoff If N0 = 0 then m0 is ignored.

- 0 < m0, 0 < m1, 0 < m2

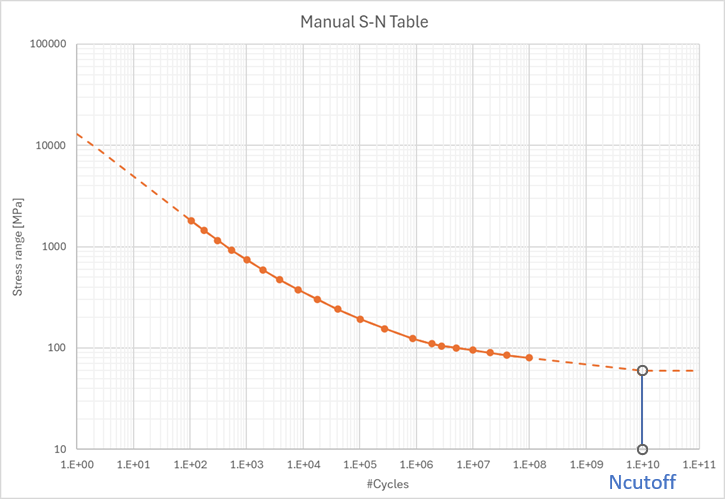

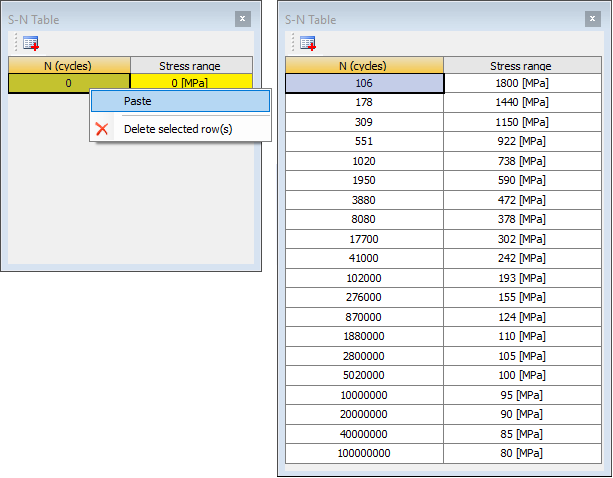

The S-N Table is used to input arbitrary stress-life data based on test data or equations (e.g. ASME).

The S-N Table used in the evaluation is automatically extrapolated down to 1 cycle and up to Ncutoff.

The following restrictions apply to S-N Table:

- At least two rows of data

- N (cycles) > 0 and in ascending order.

- Stress range > 0 and in descending order.

Tip: To enter a large table first add one row then copy the table (from Excel) and right-click in the first cell and “Paste”.

License Settings

Select “Edit License Settings = Yes” to edit the Customer ID, License Key and License borrowing time.

Select “Edit License Settings = No” to prevent the “?” on Weld Settings from an “Invalid License Key” if the license is unavailable.

Use “Check License Status” to show current users and update the License Key status.

The Customer ID and License Key credentials are saved in the Windows “User variables” and are loaded automatically when the app is started. The fields Customer ID and Licence Key displays the values partly hidden (obfuscated). The license settings are not saved with the project to prevent the credentials to accidentally be revealed if the project is shared.

When entering a new value the system “User variables” are updated and validated. Entering “0” will reset the saved values and disable the license for the current user.

If the “License borrowing time = 0” the license is not checked out when Mechanical starts.

If the “License borrowing time = 1” the license is checked out (if possible) when Mechanical starts and released when Mechanical is closed.

If the “License borrowing time > 1” the license is kept checked out on the PC for the defined number of days (even if Mechanical is closed).

Clicking the “Active License” button will release the license if needed.

See the Licensing section for more details.