Lamellar Strength

Lamellar Strength

Table of contents

About

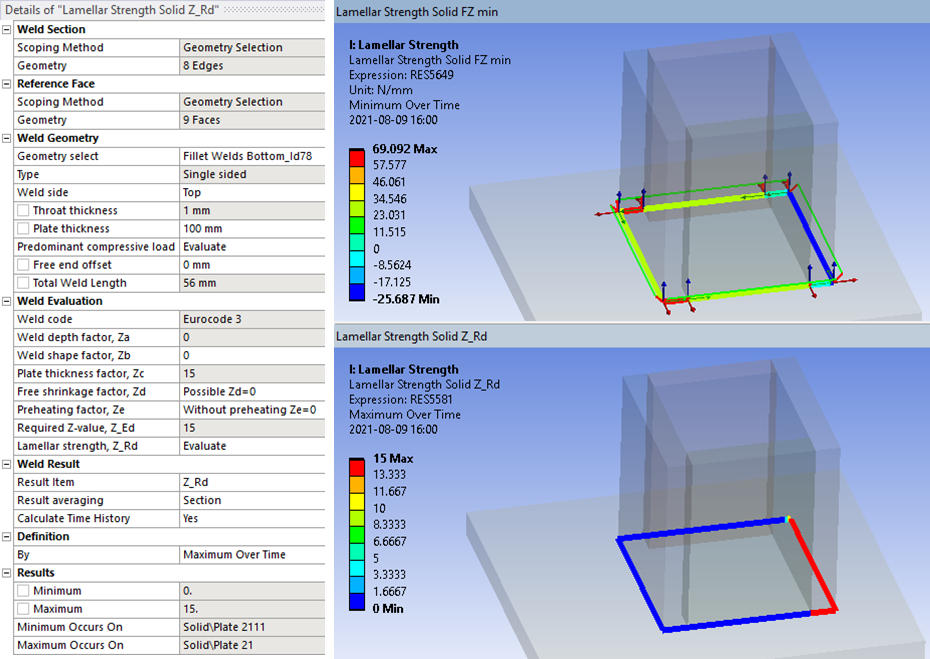

The through-thickness toughness can be evaluated with the “Lamellar Strength” according to Eurocode 3 EN 1993-1-10. A verification model is saved in system “Lamellar Strength” in “WeldToolkit-StrengthVerification_VXYZ.wbpz”, see the downloads page.

Usages

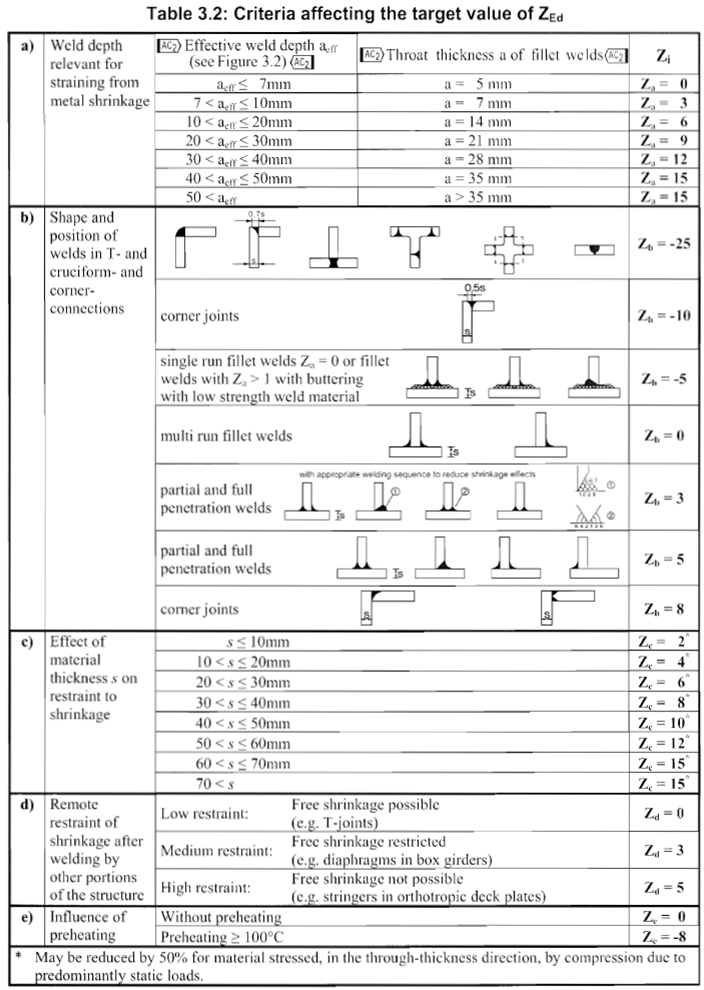

The lamellar tearing may be neglected if the following condition is satisfied: ZEd <= ZRd where ZEd is the required design Z-value resulting from the magnitude of strains from restrained metal shrinkage under the weld beads. ZRd is the available design Z-value for the material according to EN 10164, i.e. Z15, Z25 or Z35.

The required design value ZEd may be determined using: ZEd = Za + Zb + Zc + Zd + Ze In which Za, Zb, Zc, Zd and Ze are given in Table 3.2 (next page).

Select a weld to evaluate either by “Manual Select” or by a pre-defined fillet weld from the list. Set the throat plate thickness. The values for Za and Zc are automatically defined. To analyze if the weld has “Predominant compressive load” leave the list box at “Evaluate” otherwise set the value to “Yes” or “No”. If “Yes” this parameter reduces Zc by 50%.

Based on the weld geometry select “Weld shape factor, Zb” from the list, see figure below. Select options for “Free shrinkage factor, Zd” and “Preheating factor, Ze” from the list. The required maximum Z-value, ZEd, is listed based on the inputs. The lamellar strength, ZRd, can be selected from the list or set to “Evaluate”.

Inputs to the Lamellar Strength are defined in the table below. (Not complete!!)

| Geometry | |

|---|---|

| Weld Result | |

| Weld Result Parent | Select a parent result object from the list (i). |

| Result Item | Select a result item to display. (Default “Wuf”) (ii) |

| Result averaging | Section (Default) |

| Calculate Time History | No (Default)/Yes/Yes (Maximum Over Time)/Yes (Minimum Over Time). |

| Scale Factor Value | Scale factor on the calculated loads, e.g. load factor γL. |

| Definition | |

| By | Time (Default)/Result Set/Maximum Over Time/Time Of Maximum. Standard Mechanical feature (iv). |

| Display Time | Load step time for results evaluation (v). |

(i) Parent Result

To avoid duplicate names the result Id number is appended to the name. The scoping of the child is automatically set when selection the parent in the list. If the scoping of the parent is changed then create a new child result to reflect the changes or switch between two parent results in the Weld Result Parent list.

(ii) Result Item

The available Result Items are: [Section Length (Y)/Min thickness/Z_Ed/Z_Rd/FX (radial)/FY (parallel)/FZ (axial)/Fsum/MY (parallel)/Weld angle]

(iv) By

By using “Maximum over Time” the evaluation of “Predominant compressive load” checks all load steps to determine if the weld is in compression when calculating the ZEd and ZRd.

In V2025.20 the Maximum Over Time changes to use the much faster option “Calculate Time History = Yes (Maximum Over Time)”.

(v) Display Time

You may only use time steps where there are results saved, see the graph and tabular data window for load steps to use.

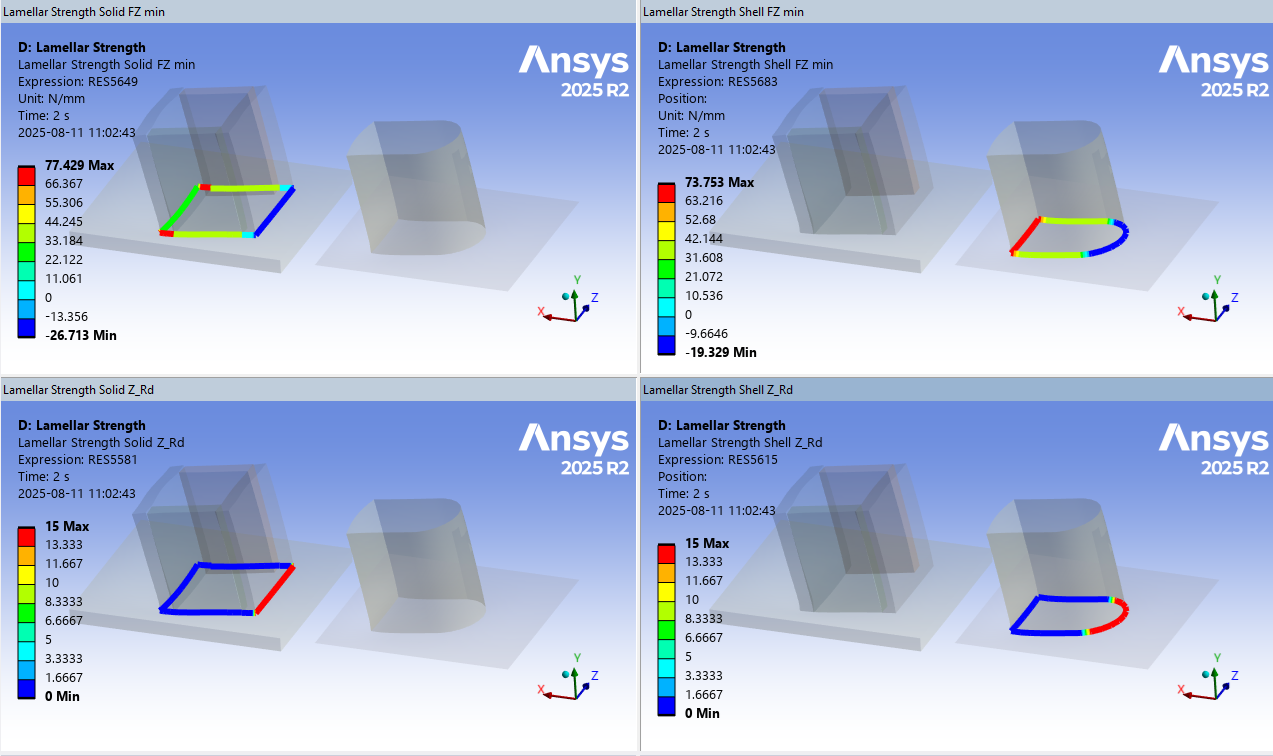

Verification

The lamellar strength case tests the influence of an always compressive load in a weld section compared to a load that changing between tension and compression.

A verification example is found in the “WeldToolkit-StrengthVerification” model. See Weld Strength Verification section.