Average Result

By default, Mechanical results typically shows a table of Minimum, Maximum and Average results at each result set. The Average value shown in the table is the nodal average, i.e. it shows ‘the sum of nodal values divided by the number of nodes’, hence the resulting (nodal) average is mesh dependent.

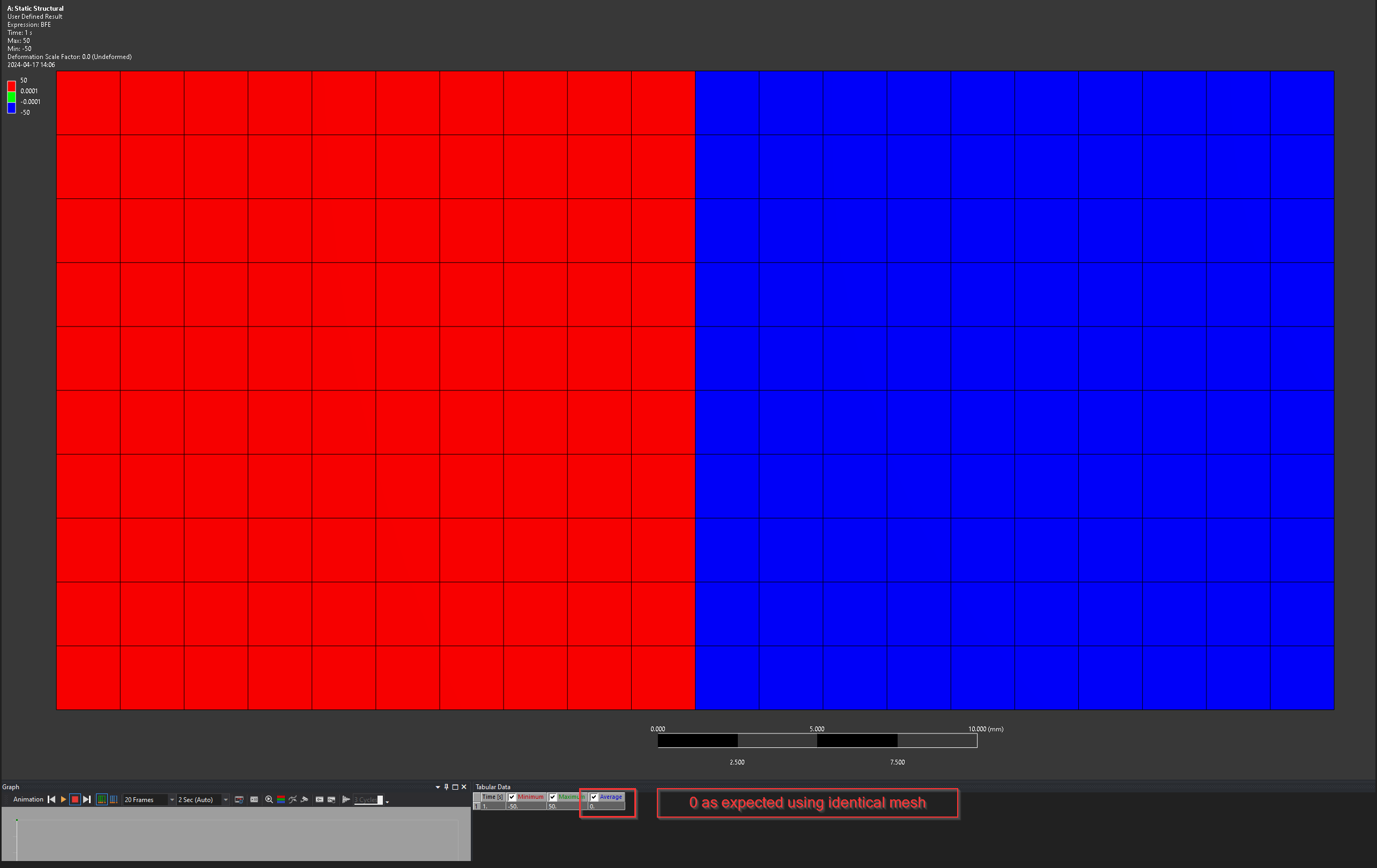

With an identical mesh for the two surfaces we get an average temperature of 0 degrees, as (intuitively) expected:

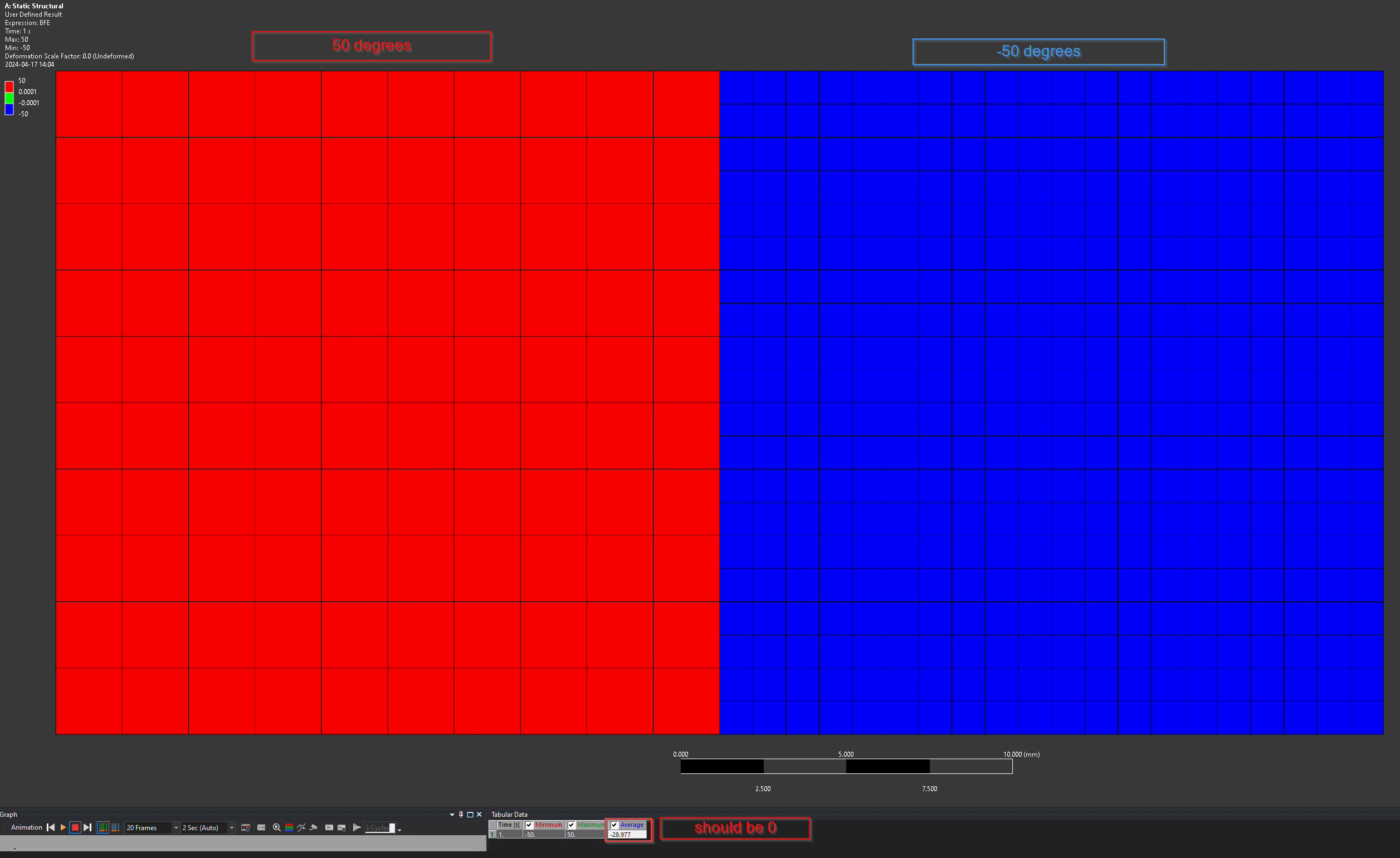

When refining the mesh on the colder surface, the average temperature reduces to -28.977 degrees.

This APDL script calculates and saves the average result value in a variable named MY_AVG on a Named Selection named MYSURF. Here we take into account the nodal area contribution from each node and finally we divide by the summed nodal area. This way, we can calculate the area-averaged result which is mesh independent.

! Commands inserted into this file will be executed immediately after the ANSYS /POST1 command.

! Active UNIT system in Workbench when this object was created: Metric (mm, t, N, s, mV, mA)

! NOTE: Any data that requires units (such as mass) is assumed to be in the consistent solver unit system.

! See Solving Units in the help system for more information.

RESUME

/POST1

SET,LAST

CMSEL,S,MYSURF

*GET,numNodes,NODE,,COUNT

*DIM,NODEAREA,ARRAY,numNodes,1

*DIM,NODEVALS,ARRAY,numNodes,1

NN = NDNEXT(0)

*DO,i,1,numNodes

NODEAREA(i,1)=ARNODE(NN)

NODEVALS(i,1)=ARNODE(NN)*TEMP(NN)

NN=NDNEXT(NN)

*ENDDO

*VSCFUN,NODEVALS_TOT,SUM,NODEVALS(1)

*VSCFUN,SUMAREA,SUM,NODEAREA(1)

MY_AVG=NODEVALS_TOT/SUMAREA

ALLSEL